The Difference Between Milling and Turning

We have meet this question the difference between milling and turning from many our clients. They say something to the extent of, “Help me understand what is turning and what is milling, because to me it is all machining.” CNC turning and milling are two types of precision machining, but exactly what is the difference when it comes to precision machining?

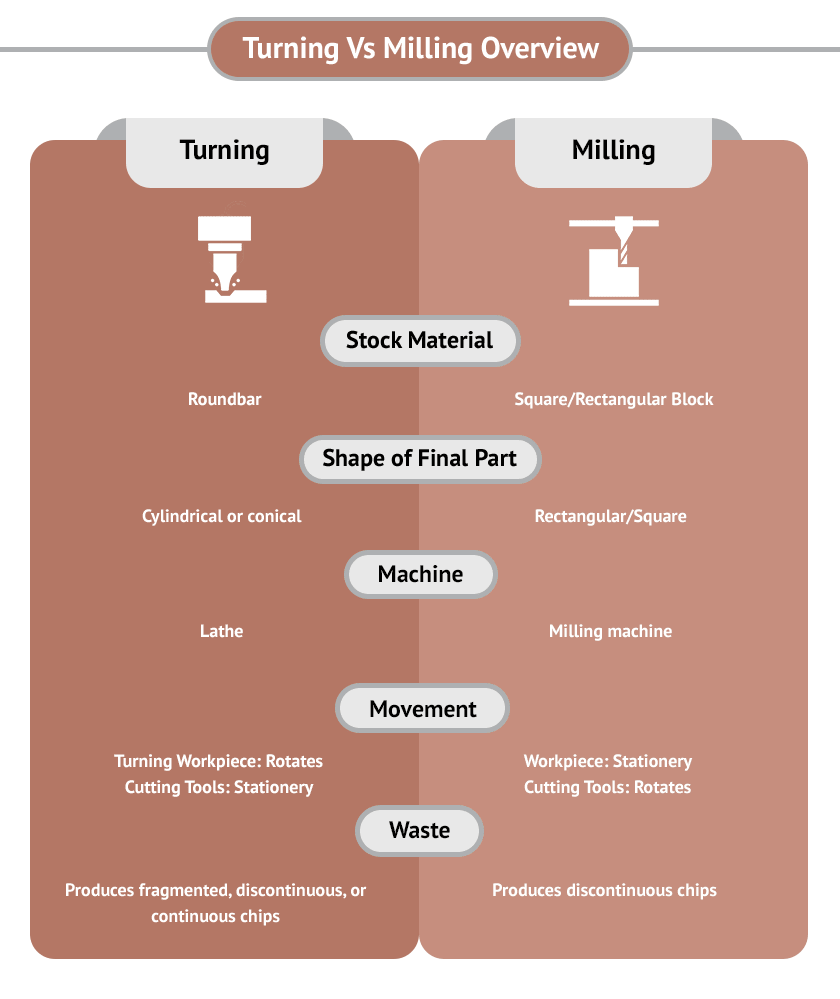

The short answer is that

- Turning rotates the workpiece against a cutting tool. It uses primarily round bar stock for machining components.

- Milling spins the cutting tool against a stationary workpiece. It uses primarily square or rectangular bar stock to produce components.

Turning and Milling Similarities:

Both use a controlled processed to remove unwanted material from the stock material: subtractive manufacturing. Both processes produce chips of waste material as the tools machine out the required features. However, the stock material, machining methods and tools differ from each other.

Both use the latest in Computer Numerical Control (CNC) technology, in which engineers program the machines using Computer-Aided Design software (CAD). This requires less supervision during operation and minimizes human error, giving manufacturers a faster and more reliable way to deliver consistent quality.

Like many types of CNC machining, turning and milling are both appropriate for metals like aluminum, steel, brass, copper, and titanium as well as an array of thermoplastics. Unsuitable materials include rubber and silicone (too soft) and ceramic (too hard).

Like most subtractive manufacturing techniques, turning and milling generate heat and often employ cutting fluid to mitigate this issue.

CNC Turning Distinctions

With CNC turning machines (lathes), a chuck (griping mechanism) holds the round bar stock and a spindle spins the chuck (and bar stock) at a preset RPM as it moves through the machine. The speed of this movement will vary by machine, material being used and features of the component.

A stationary cutting tool is continuously applied to the surface of the rotating (turning) bar stock, shaving away unwanted material. Several cutting tools move in and around the bar stock to create the needed features on the component.

There are many kinds of CNC lathes with various types of tooling options, spindle options and outer diameter limitations. CNC lathes usually produce round shapes, though some hexagon shaped bar stock may also be turned.

Some CNC turning centers have one spindle, allowing work to be done all from one side, while other turning centers, have a main and sub-spindle. In this setup, a part can be partially machined on the main spindle, moved to the sub-spindle and have additional features added to the other end of the component. This allows for dropping a part “complete” off the machine, with no additional equipment needed to machine all the features.

Some CNC Swiss turning machines utilize “live” tooling, which can stop the rotation to add additional features like drilled holes, slots and small milled features. This technique allows for a wider range of shapes, sizes and material types.

Turned parts are usually quicker and more efficient to produce than milled parts. They are also often smaller than milled parts.

CNC Milling Distinctions

CNC milling equipment rapidly rotates a cutting tool against the surface of a stationary workpiece. The spindle holds the cutting tool (milling cutter), which spins at high RPMs and removes material. A milling cutter can have 2–150 cutting surfaces, and some have even more.

Milling operations are usually reserved for flat or sculptured surfaces on square or rectangular blocks.

If you have request for milling and turing parts, please contact us!

Please refer this link to find more detail information: Turning Vs. Milling: What’s the Difference for Precision Machining?

发表评论

Want to join the discussion?Feel free to contribute!